Pelletization is a process of agglomeration that transforms a fine powder mixture of drug(s) and excipients into small, free-flowing, spherical entities known as ‘pellets’.

The method is essential for creating pellets that are uniform in size, possess a high drug loading capacity, and also mitigate segregation and dust.

Rationale for Pelletization

- Prevention of the segregation of co-agglomerated components leads to enhanced uniformity of the content.

- Prevention of dust generation enhances process safety, as fine powders can lead to dust explosions and inhalation of fines may result in health issues.

- Increasing bulk density while reducing bulk volume; the specified shape and weight enhance the product’s appearance.

- Enhancement of handling characteristics, attributed to the free-flowing nature of the material;

- Improvement in the hardness and friability of pellets.

The controlled release application of pellets is facilitated by their optimal low surface area-to-volume ratio, which offers an ideal configuration for the application of film coatings.

Benefits of Pellets

- Pellets disperse readily in the gastrointestinal tract, enhancing drug absorption and reducing local irritation of the mucosa caused by certain irritant medications.

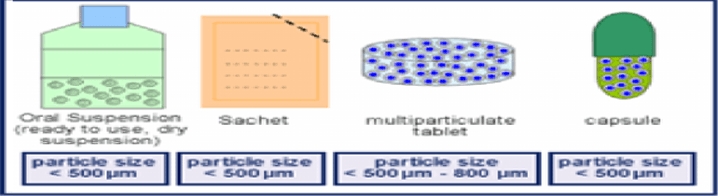

- Pellets present a high level of flexibility in the design and development of oral dosage forms such as suspensions, sachets, tablets, and capsules.

- They can be segmented into the required dosage strength without any alterations to the process or formulation.

- When the pellets that contain the active ingredient are presented as a suspension, capsule, or disintegrating tablets, they provide significant therapeutic benefits compared to single unit dosage forms.

- Additionally, they can be mixed to deliver incompatible bioactive agents.

- They can also be utilized to achieve varying release profiles at the same or different locations within the gastrointestinal tract.

Enhanced Flow Characteristics: Spheres exhibit outstanding flow properties that can be utilized in automated processes or in situations where precise dosing is essential. E.g.: Tableting, molding operations, capsule filling, and packaging

Coating: The application of a coating on granules is frequently utilized to stabilize active ingredients within the granule or to regulate the release of these active components. Common uses in the pharmaceutical sector include controlled release medications. The simplest shape to coat is the sphere, as it lacks edges.

It is also the most cost-effective option for coating since no additional coating material is necessary to address the irregularities present on the surface of the granules.

Density increase: Both the true and the bulk density of granules are increased by spheronising. This can improve the process and the packaging

Hardness and Friability: The properties of hardness and friability are influenced by the internal cohesive forces and the characteristics of the surface. Spheronisation enhances the hardness while decreasing the friability of granules. Consequently, this process minimizes the quantity of fines produced during handling or transportation.

Drawbacks of Pellets

- Dosing is conducted by volume instead of by quantity, and it is divided into individual dose units as necessary.

- This process includes capsule filling, which may elevate costs, or tabletting, which can damage the film coatings on pellets.

- The dimensions of pellets differ from one formulation to another, typically ranging from 1 to 2 mm.

- Certain pellets cannot be compressed into tablets due to their excessive rigidity. In such instances, these pellets must be encapsulated within capsules.

- The manufacturing of pellets is frequently a costly endeavor and often necessitates highly specialized machinery.

- Moreover, managing the production process poses significant challenges.

Desirable characteristics of pellets

Uncoated Pellets:

- Uniform spherical shape

- Unform size

- Good flow properties

- Reproducible packing

- High strength

- Low friability

- Low dust

- Smooth surface

- Ease of coating

Once Coated Pellets:

- Maintain all of the above properties

- Have desired drug release characteristics.

PELLETIZATION TECHNIQUES

- Powder Layering technique

- Suspension / Solution layering technique

- Extrusion and Spheronization

- Spherical Agglomeration

- Spray Drying and Spray Congealing

- Melt Spheronization

- Cryopelletization