- Pan Coating

- Fluid Bed Coating

PAN COATING OVERVIEW

Functions of the parts

- Coating Pan: Used for tablet coating

- Solution preparation vessel: Used for preparing the coating solution

- Holding tank: Hold the coating solution

- Pumping System: To pump the coating solution to the gun

- Spraying System: Sprays the coating solution inside the coating pan onto the tablets

Inlet & Outlet System of a Pan Coater

Inlet of the Pan

- Inlet air filtration with normal and HEPA filters

- Air heating system

- Humidification / dehumidification

Outlet of the Pan

- Solvent recovery system

- Bag house or scrubber

- Outlet air with or without HEPA

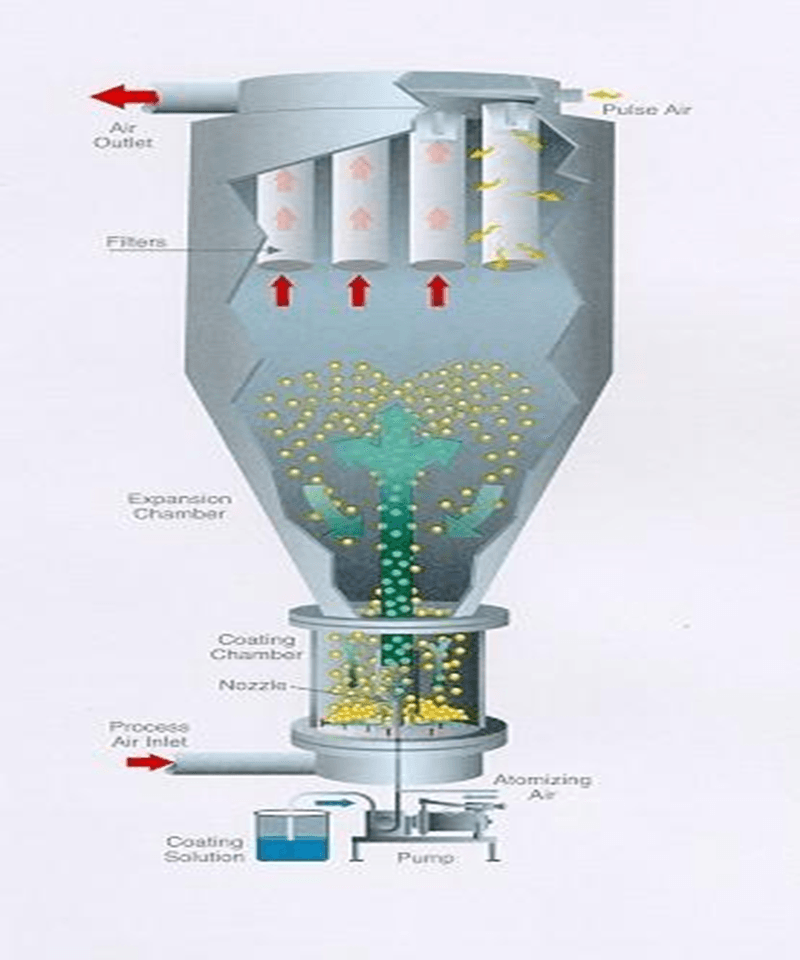

FLUID BED COATING (WURSTER COATING)

FBC is a technique for coating pellets, spheres, particles or granules using a spray of solution inside a column.

The spray nozzle is installed in the base plate, which creates a spray pattern that aligns with the air feed. By employing a Wurster cylinder along with a base plate featuring various perforations, the particles intended for coating are accelerated within the Wurster tube and simultaneously directed through the spray cone.

As the particles ascend, they dry and subsequently fall outside the Wurster tube, returning to the base plate. They are then redirected from the exterior back into the tube, where they are accelerated by the spray once more. This process results in a remarkably uniform film, ensuring that particles of varying sizes receive an even coating.