The analysis will be carried out in the lab and after analysis if the received material is appropriate (complying with all the specific limits) Material will be released by the QC which means it can be used for the Packing of the Material.

For Primary Material:

- Description

- Physical Parameters

- Type of Glass Testing for Glass materials

- DSC (Differential Scanning Calorimetri)

- Biological tests

- TAMC (Total aerobic microbial count)

- Bacterial Endo toxin test (BET)

- IR

- Physico Chemical Tests

- UV

- WVPTR (Water Vapor Permeation Transmission Report)

- Structural Analysis

- Grammage (Heat Seal Coating & Aluminum foil)

- GSM (Weight /Area)

- Induction Cap Sealing

- Water content (LOD)

- Adsorption Capacity

- Pin Holes

- AQL Acceptable Quality Level

- Structure

For Secondary & Tertiary Material:

- Description

- Text & Color

- Dimensions

- Grammage /GSM (Garm per sq. Meter)

- LOD

- Shade

- Printing

- Bursting Strength

- Performance

Different type of testing procedures and instruments used:

Dimensions:

Any Material which we are procuring from Outside/ Vendor should be as per our requirement as a part of Analysis the Material needs to be verified / checked. This test specifically used to determine the Dimensions i.e. Length, Width & Height of the Sample So that we can assess the Measurements of the sample and it should be as per our requirement.

By Using a Calibrated Scale we can measure the Dimensions of the Sample. The scale may be having the least count of 1mm or 1/2mm.

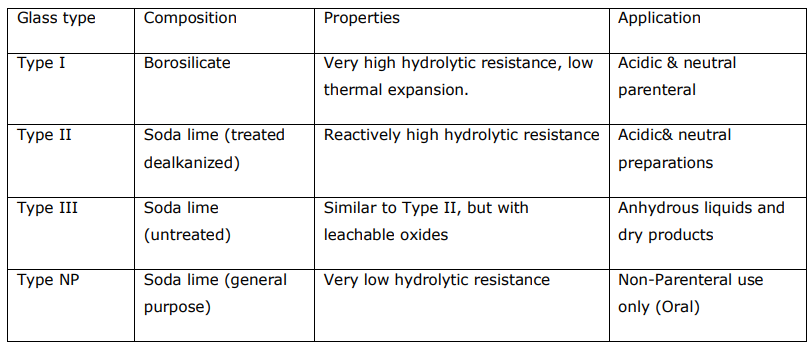

Glass Alkalinity Test: Test for type of Glass:

To know the type of glass used in the Material of construction. To determine that up to what extent the Glass is chemically inert in nature.

Glass can be classified on the basis of its properties of reactivity and its composition.

Kensa Easy Comparison Device:

This is special Equipment which is meant for the verification of the Text Matter i.e. Text Matter of different Languages / Symbols can be easily verified. By using this equipment we can save the Time & Human Effort.

Parts: Monitor, Manuscript Board, Fluorescent Lights, Operating Panel.

In this equipment different options are there in the Operating Panel which helps to increase the brightness, density, Clarity and Zooming of the samples.

A standard Specimen for reference will be there for each & Every Printed Material. In this initially we will Place the reference / Approved specimen on the Manuscript Board, the text matter of the sample which we place on the Manuscript board will reflects on the Monitor and that can be saved. Then we need to place the sample on the Manuscript board it also reflects on the Monitor and the approved specimen which we saved initially will be overlaid with the sample there we can easily identify the abnormality/ discrepancy in the sample.

Barcode Scanner:

Barcode is like a security system which plays a vital role in Pharma Industry which assists in different ways like tracking as well gives unique identification from other imitating products.

A barcode reader (or barcode scanner) is an electronic device for reading printed barcodes. It consists of a light source, a lens and a light sensor translating optical impulses into electrical ones. Barcode reader contains decoder circuitry analyzing the barcode’s image (Numbers) data provided by the sensor and sending the barcode’s content to the scanner’s output port / Print.

For all Packaging Materials having Barcode we should verify the Barcode with Barcode Scanner. A standard Specimen for reference will be there for Packaging Material. In this initially we will scan the specimen copy and then we need to scan 10 samples if any mismatch is there we can identify it.

Bursting Strength:

The maximum uniformly distributed pressure applied at right angle to its surface that a test piece will stand under standardized conditions (Measuring Units: kg/cm2, lbs/in2 and kpa).

The ability of the sample which can withstand when pressure applied on it so that we can assess the quality & strength of the sample, for determining this we are using the Bursting strength apparatus.

The samples to be tested should be placed in the board head or Paper head, the hydraulic pressure required to burst a sample will be applied from the bottom of the sample with the help of a rubber as the pressure increases the sample starts bursting and at certain pressure the sample completely burst out. The pressure applied for burst of a sample can be taken as the bursting strength.

Moisture content:

This test is mainly used to determine the amount of Water content present in the sample. In this test initially we will take the sample weight and the sample needs to exposed to certain temperature (depends on the kind of Material) and the final weight after drying needs to be taken.

We can calculate the amount of moisture present in the Sample by calculating the difference between the Initial and Final Weights.

This test is normally performing by using Hot Air Oven (i.e. an Instrument which is capable of Providing Artificial Environment- Temperature) within the Instrument

Differential Scanning Colorimeter:

Differential Scanning Calorimetry (DSC) measures the temperatures and heat flows associated with Transitions in materials as a function of time and temperature in a controlled atmosphere.

These measurements provide quantitative and qualitative information about physical and chemical changes that involve endothermic or exothermic processes, or changes in heat capacity.

– It mainly helps to evaluate the Melting Point of the sample and the standard which helps to assess the Quality of the sample i.e. HDPE LDPE etc,

In this prescribed temperature should be maintained i.e. 40°c – 200°c.

We use Nitrogen Gas as it acts as good carrier. Allow the Instrument to warm up for at least 30min before performing an Experiment / Analysis. Compressed Air line will be there along with Nitrogen line for Finned Air Cooling System (FACS).

All the Parameters required should be adjusted as per Method (Particular method for particular Material) and details of the material also needs to be entered.

An empty Pan should be used as a reference. Initially standard needs to be run and then sample. Run time is 47.40min. After the runs, calculate the difference between the standard and sample Thermo grams obtained. The difference should not be more than the specified Limits.

Water vapor Permeation Test:

This test plays a vital role in identifying the containers capability/Properties i.e. the amount of Moisture Permeates from the External Environment in to the bottles can be identified. For this a prescribed procedure is given in the US Pharmacopeia.

In this 12 containers needs to be taken of Uniform size and type. Clean the surface with Lint free cloth, close and open each container for 30times. Apply the closure firmly and uniformly each time the container is closed. Close screw capped containers with a torque that is within the range of tightness specified. Add Desiccant to 10 of the Containers, filling each to within 13mm of the closure. If the Container volume is 20 ml or more or filling each to two-thirds of capacity if the container volume is less than 20ml.

If the Interior of the container is more than 63mm in Depth, an inert filler or spacer may be placed in the bottom to minimize the total weight of the container and desiccant, the layer of desiccant in such a container shall be not less than 5cm in depth. Close each immediately after adding Desiccant, apply the designated Torque when closing screw capped containers. To each of the remaining 2 containers, designated controls add a sufficient number of glass beads to attain a weight approximately equal to that of each of the test container and close apply the designated Torque when closing screw capped containers.

Record the Weight of Individual containers and store at 75±3% RH and temperature at 23±2°. After 336±1hr (14 days) Record the Wait of the Individual container in the same manner.

Also take the average volume for 5 containers before calculation

Calculation:

(1000/14V)[(Tf-Ti)-(Cf-Ci)]

V- Volume in ML

(Tf-Ti)- Difference in MG, between the Final and Initial Weights of Test

Containers

(Cf-Ci)- Difference in MG, between the average Final Weight and average

Initial Weights of 2 Controls

The Results obtained should be as per the Limits…

Adsorption Capacity:

By this test the amount of Moisture absorbed by Sample can be determined. It mainly requires for Sensitive Primary Packaging Material like Silicagel. Silicagel present in different packs like Bottle Pack, card Board Pack plays vital role in absorbing the Moisture and protects the drug to contaminate from the Moisture. So this test is mandatory for sensitive packing Material like Silica ge

Torque Test:

Torque is the force applied to a closure (Cap) to fit in to a Container (Bottle). Torque tester is utilized to determine the Torque of the sample. In this Instrument Container with closure should be placed and required amount of torque should be applied for exact fitting of cap to the Bottle.

A Prescribed Tabular format is available which indicates the amount of Torque required for different size Caps & Bottles.

IR: Identification by IR

This test is mainly useful to determine whether the type of composition used for the Packing Material is appropriate or not which means it’s a kind of Identification test. If the Material is appropriate then the peaks retained after the scan will be same with the Reference/Standard Spectrum. Useful mainly for HDPE, LDPE, CAPS, Foils, Silica gel Canisters.

Two ways of Identification is mainly in progress by Comparing with the reference spectrum which was already present as Master or By Comparing with the Standard spectrum i.e. Standard also will be scanned along with sample and both should be overlaid for comparison.

One Special Accessory with IR Instrument is also available for ID by IR of Packaging Material i.e. UATR-Universal –Attenuated Total Reflectance

UV:

It helps to determine the capacity of the Material to withstand the Environment (different Wavelengths) in order to protect the inside drug. A different accessory is there for Packing Material.

Humidity Chambers: plays an Important Role in Packing Material Analysis. The Instrument is Specially Designed in order to maintain the required Temperature along with humidity as well.

Text Proof Reader: Is a latest model of instrument which is useful for verification of text Matter

Induction Cap Sealing: Induction sealing is a non-contact process, which is used to bond a foil disk or to seal the opening of a container. The technique provides the user with a tamper evident seal. The seal assures product integrity and prevent any chances of leakage. It increase the products shelf life, reduce pilferage, and ensures maximum customer satisfaction.

Wad

Wads are inner seal materials, which are available in different variations to meet almost any standard or customized packaging need. Modifications can be made to suit the types of container, closure and product. There is almost no limit to the size of container, the Wad’s can seal. The typical induction inner seal begins with a multi-laminate liner inside a closure. It is made up of following layers:

A layer of pulp board

A layer of wax

Aluminum foil

A layer of polymer (Heat sealable film)

Operating Principle

The principle of operation lies in the cap, which passes through an electromagnetic field generated by an induction cap sealing machine. The electromagnetic field induces a high electric current in the foil of seal. This causes the foil in the seal to heat. A coating laminated to the aluminum disk fuses and softens to the mouth of the bottle.

Pin Hole Tester:

Pin Hole Tester is the Instrument used to detect the Gaps / Pin Holes Present in the Primary Packing materials like foils.

Some of Images of Different Pin Hole Detectors.

The article is well detailed on the testing requirements.

Can you please share kensa easy comparison device website or supplier details