TABLETS:

Tablets are the solid pharmaceutical dosage forms containing drug substances with or without suitable diluents and prepared either by compression or molding methods.

Advantages of Tablets:

- Convenient to use and are an elegant dosage form

- Formulated to offer rapid drug release or controlled drug release

- In-expensive dosage form

- Easily manufactured to show product identification

- Easier to mask the Taste of bitter drugs

- Simple and stable

- Convenience in packaging, shipping and dispensing

- Accuracy of dosage

- Compactness

- Portability

- Ease of administration.

Disadvantages of Tablets:

- Manufacture of Tablets involve a series of unit operations.

- More product loss at each stage in the manufacturing process.

- Absorption of therapeutic agents from Tablet is dependent on physiological factors

- Compression properties of certain therapeutic agents are poor and may present problems in their subsequent formulation and manufacture as Tablets.

- Administration of Tablets to certain groups, e.g. children and the elderly may be problematic due to difficulties in swallowing. These problems may be overcome by using effervescent tablet dosage forms.

EXCIPIENTS USED IN THE MANUFACTURE OF TABLETS:

In addition to the active ingredient, solid dosage forms will also contain a range of substances called excipients. The role of excipients are essential in ensuring that the manufacturing process is successful, and the quality of resultant formulation can be guaranteed.

Excipients are useful in the manufacturing process, to aid in the handling of the active substance concerns such as by facilitating powder flowability or non-stick properties, in addition to aiding in vitro stability such as prevention of denaturation or aggregation over the expected shelf life.

A typical Tablet contains:

The selection of appropriate excipients also depends upon the route of administration and the dosage form, as well as the active ingredient and other factors.

Excipients are categorized into groups according to their main functions, although some may be multifunctional. Examples of commonly used excipients in the manufacturing of Tablets are as below:

TABLET TYPES:

- Conventional compressed Tablets

- Multiple compressed Tablets

- Enteric-coated Tablets

- Sugar-coated Tablets

- Film-coated Tablets

- Chewable Tablets

- Effervescent Tablets

- Buccal and sublingual Tablets

- Vaginal Tablets

CONVENTIONAL COMPRESSED TABLETS:

- These Tablets are designed to provide rapid disintegration and hence rapid drug release.

- The manufacture of these Tablets involves the compression of granules or powders (both containing drug) into the required geometry.

- The Tablets will disintegrate within the gastrointestinal tract (stomach), allowing the drug to dissolve in the gastric fluid and, ultimately, be absorbed systemically.

MULTIPLE COMPRESSED TABLETS:

These are tablets that are composed of at least two layers.

There are two designs of multiple compressed Tablets

(1) Multiple-layered

(2) Compression coated

Multiple-layered Tablets:

- First layer is formed by a relatively light compression of the drug containing powder mix/granules.

- The next layer is then formed by compression of the powder/granule mix (containing drug) on top of the lightly compressed first layer.

- Additional layers are formed in a similar fashion.

Compressed Coated Tablets:

- The initial layer is prepared by light compression, removed and located in a second tablet press.

- The granules/powders of the second coat are fed into the press and allowed to form a constant mass around the surface (and edges) of the pressed tablet prior to compression to form the finished product.

ENTERIC-COATED TABLETS:

- These are Tablets that are coated with a polymer that does not dissolve under acidic conditions (ex: the stomach) but does dissolve under the more alkaline conditions of the small intestine.

- These offer protection against possible drug degradation (ex: Erythromycin) or irritation of the gastric mucosa (ex: non-steroidal anti- inflammatory drugs).

- Examples of polymers that are used in enteric coating: Hydroxypropylmethyl cellulose succinate, methacrylic acid co-polymers (Eudragit), Cellulose acetate phthalate/cellulose acetate butyrate.

SUGAR-COATED TABLETS:

- These are conventional Tablets that have been coated with a concentrated sugar solution to improve the appearance of the formulation and / or to mask the bitter taste of the therapeutic agent.

FILM-COATED TABLETS:

- These are conventional Tablets that have been coated with a polymer or a mixture of polymers (and, when required, a plasticizer to render the coating flexible).

- Film coat show improved mechanical properties when compared to sugar coatings.

- Film coat may be deposited over embossed markings on the tablet surface.

- Film coat are employed to control the rate and duration of drug release or to target drug release to certain regions of the gastrointestinal tract, e.g. the colon.

- Examples of polymers that are used to film-coat tablets: Hydroxy propyl methylcelluose, hydroxy propylcellulose, Eudragit E100.

CHEWABLE TABLETS:

- These Tablets are chewed within the buccal cavity prior to swallowing.

- Administration to children and adults who have difficulty in swallowing conventional Tablets

- Antacid formulations in which the size of the tablet is normally large and the neutralization efficacy of the tablet is related to particle size within the stomach.

EFFERVESCENT TABLETS:

- Effervescent tablets are added to aqueous solutions where they will rapidly disintegrate and produce either a drug suspension or an aqueous solution.

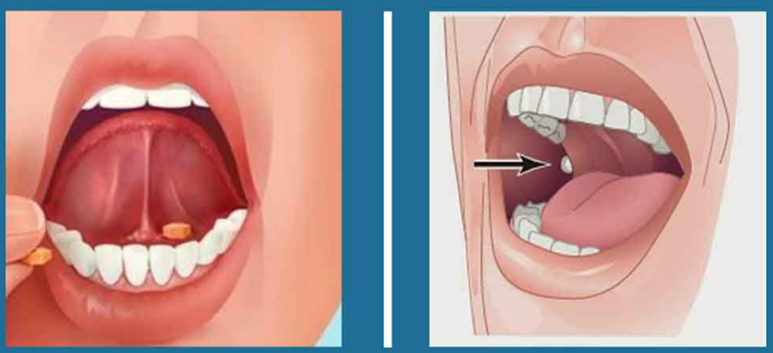

BUCCAL AND SUBLINGUAL TABLETS:

- Buccal and sublingual Tablets are dosage forms that are held within the oral cavity and slowly dissolve; the drug is absorbed across the buccal mucosa to produce a systemic effect.

- Buccal Tablets are positioned between the cheek and the gingiva whereas sublingual tablets are positioned underneath the tongue.