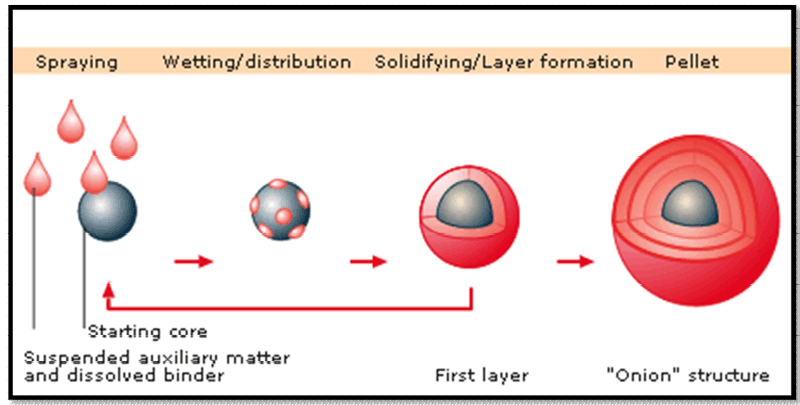

This method entails the application of successive layers of a solution and/or suspension containing drug substances and binders onto starter seeds, which can consist of inert materials or crystals of granules of the same drug.

In this method, drug particles and other components are either dissolved or suspended in the application medium. The droplets strike the starter seeds or cores and distribute uniformly as the solution or suspension is sprayed onto the cores. The subsequent drying phase enables the dissolved material to crystallize, creating solid bridges between the cores and the initial layer of drug substances, as well as among the successive layers of drug substances or polymers. This process is continued until the desired layer of drug or polymer is formed.

This technology purports to enhance the movement of products in a specified direction across all equipment utilizing the disk jet gas distribution plate. Additionally, a three-component spray nozzle is employed to facilitate improved film formation on the pellets, owing to a consistent and reproducible drop size distribution. The ability to access clogged nozzles without halting or disrupting the process renders this equipment superior to the Wurster system. Huettlin’s three-component nozzle features an extra channel that allows for the introduction of a second gas or component, thereby creating a unique microclimate around the nozzle that helps to prevent excessive spray drying or nozzle clogging. Such microclimates near the nozzle openings are particularly beneficial when a film former with a relatively high minimum film forming temperature (MFT) is utilized. For instance, the MFT of aqueous shellac suspensions ranges from 35 to 55 degrees, contingent upon the chosen plasticizer.